Nov 2020

Liquid Systems Invests in Further In-House Manufacturing

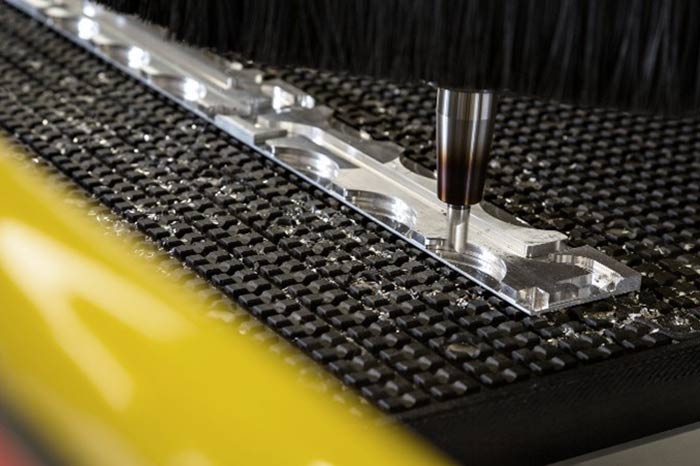

Demand being what it is, we have just taken delivery of yet another milling machine: a MX330 PC10 five axis vertical oriented 4m x 4m footprint of high technology and metal. While we have been machining aluminum wine bottle racks at our Squamish facility since our inception 10 years ago, we thought we would take a moment to highlight the importance to our business (and ultimately what we deliver to the customer) of investments with in-house manufacturing.

More Capacity and Shorter Lead Times

We continue to enjoy a high calibre local supply chain of manufacturers and finishers here in the lower mainland of British Columbia. Our made in Canada lineage has always been an important part of our identity here at Liquid Systems and we have great partners to help us along the way. Given the growth in demand we have been experiencing however (a good problem to have!), it is important that we can react quickly to ensure a steady and timely supply of parts. This added machine will lend us more capacity to buffer against pinch-points in our supply chain, as well enable us to own our own production planning to decrease lead times as much as possible and bring the customer their wine racks faster.

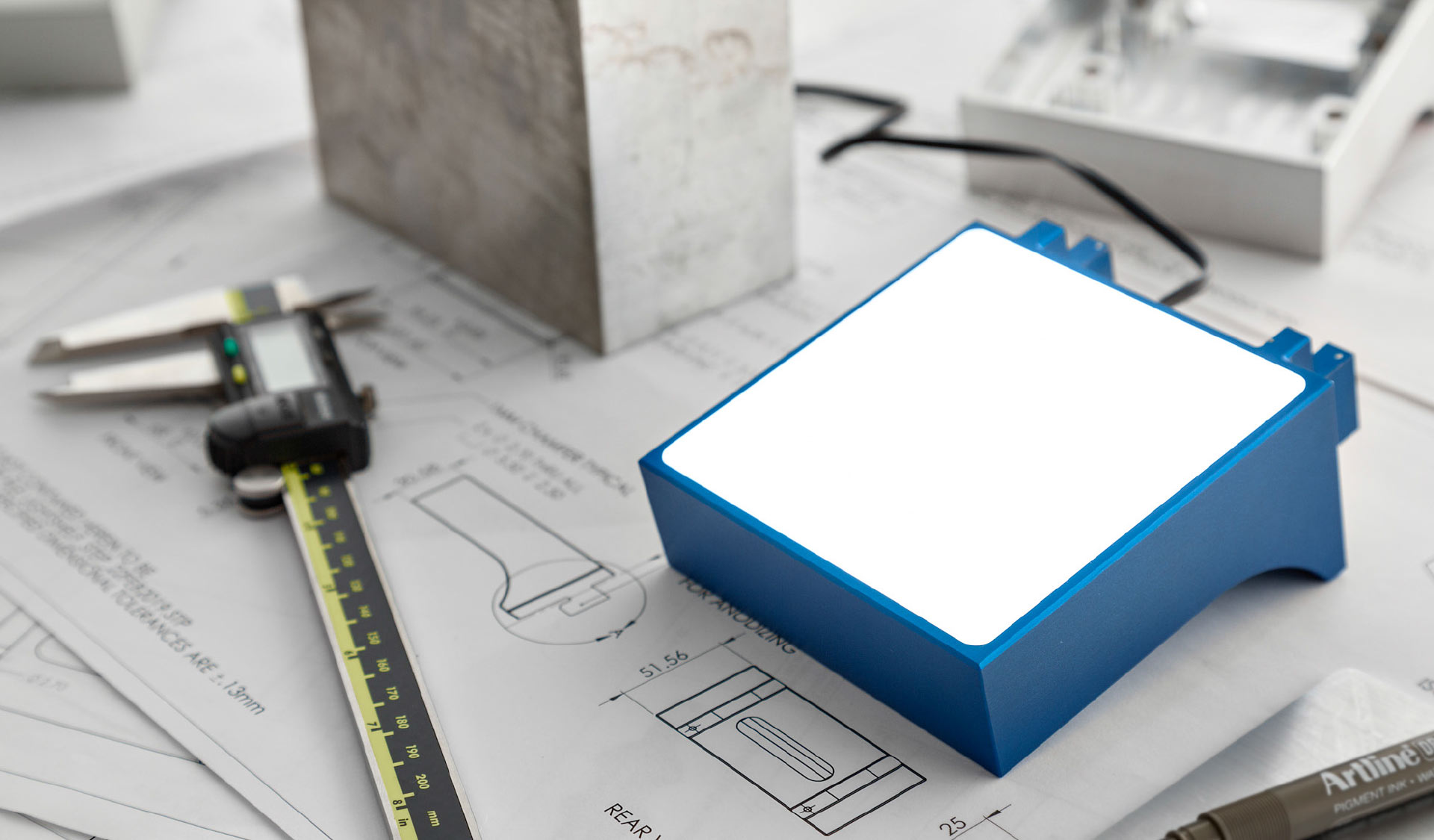

The MX330 PC10 precision milling machine

Innovation and Better Product

Liquid Systems wine racks were born from a void in the market for premium aesthetically and functionally driven options. Our patented system is a result of countless iterations, prototypes and the trials and tribulations of inventing and commercializing something new. Advancements in the wine rack industry and technology over-all are not lost on us and with added in-house milling capacity, we open-up more bandwidth for ongoing improvements in design let alone whole new additions to the Liquid Systems family of products.

Quality Control

Having carefully developed the best supply chain for aluminum wine racks through a network of raw material suppliers, machinists and anodizing services we have every faith in the quality of our product. After all, premium product has no margin for imperfection. When your wine rack depends on 1/3000-inch tolerances of aircraft grade aluminum, and anodized colour shade differences between posts and fins are completely unacceptable, your quality control needs to be of the highest standard. We manually inspect all components before shipping to our customers. However, having the ability to inspect during and immediately after production enables us to identify potential problems earlier and effect immediate remedies within a smaller time frame. We also gain the ability to improve quality assurance and process efficiencies by virtue of, quite literally, first-hand knowledge.

Socio-Environmental Benefits

We live in a global economy and an interdependent world. While international supply chains are part of everyday commercial reality (and there is nothing wrong with that if they are properly managed) there are benefits that go beyond a business advantage to keeping our production close to home. We are proud to call Squamish home and being able to provide employment to locals who share our vision of community and values is an important part of our identity. Our version of a social audit is to look up (or even better, get up) from our desks and engage with our designers and metal magicians about work, how its going, how can they be supported and what cliff they climbed on the weekend or bike trail they discovered.

From an environmental standpoint, being closer to home has merit too. To take one example, being able to visit an anodizing service and see the processes in action and ask questions offers the chance for “sniff-tests” of regulatory practices. This would be beyond our capacity with off-shore sourcing. Another example is shipping: all else being equal, a more intimate supply chain usually limits transportation related emissions.

Capacity, innovation, quality control and other benefits will see Liquid Systems continue to make investments with in-house manufacturing. Next time you take delivery of your custom wine cellar or display, we know you too will reap the rewards!